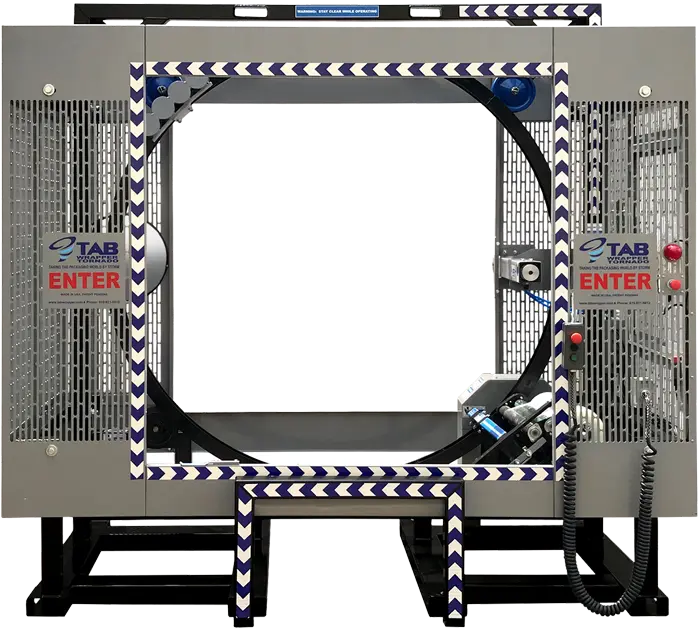

TAB WRAPPER TORNADO - SMART CONTROLS

Automated Wrapping with One-Button Operation

Meet the TAB Wrapper Tornado with Smart Controls — where semi-automation meets exceptional performance. With a one button press, this intelligent system transforms semi-automatic pallet wrapping into a streamlined, precision operation that delivers superior speed, efficiency, and safety.

TAB WRAPPER WITH SMART CONTROLS IN ACTION

WHY CUSTOMERS CHOOSE THE TAB WRAPPER WITH SMART CONTROLS

When you need to move on from the manual wrapping process and want the flexibility of semi-automatic wrapping, the TAB Wrapper Tornado with Smart Controls delivers the perfect balance. This upgraded system eliminates the need to hold down buttons while still providing precise control over the wrapping process.

- One-button operation: Start continuous wrapping with a single press of the start button

- Prime/Home function: Automatically returns the dispenser to its starting position for quick, consistent operation

- Auto-Cut: Cuts the stretch film automatically when the wrapping process is complete

- Enhanced safety: Includes emergency stop, safety relays, and an optional two to three-safety scanner upgrades to protect employees

- Increased efficiency: Faster cycles with minimal operator involvement

- Wireless remote option: Optional remote for added flexibility and control, so forklift drivers don’t have to leave their seat

Curious how much you could save by automating your wrapping process? Try our ROI Calculator to see your potential savings.

HOW THE TAB WRAPPER WITH SMART CONTROLS MODEL WORKS

Smart Controls takes our proven TAB Wrapper technology and adds even more automation that simplifies the wrapping process. With enhanced features that handle positioning, cutting, and film management automatically, operators can focus on moving loads while the system does the precision work:

- Once the forklift driver has the pallet in place, the driver presses the start button. The Smart Controls automatically positions the film dispensing unit using the position encoding system.

- The system starts encircling the pallet load with continuous 360° wraps around and under both the pallet and product.

- The driver can move gradually forward or backward as needed while the system runs continuously until wrapping is complete.

- The driver presses the stop button when finished.

- The Smart Controls automatically cuts the stretch wrap, and the driver can drive away and return with the next pallet. The pallet is now stable, unitized, and ready for transport with no additional securing needed.

Smart Controls Model Sizes

- 80″ Fits up to 48″ x 48″ skid

- 100″ Fits up to 60″ x 60″ skid

- 115″ Fits up to 50″ wide x 95″ tall

Have any other questions about the Smart Controls Model or our other models? Find answers and more details on our FAQ page.

Our Complete Tab Wrapper Tornado Lineup

The TAB Wrapper Tornado lineup includes a variety of models, from everyday pallet wrapping to high-volume, fully automated operations. Whether you need a reliable manual option, advanced programmable controls, or a conveyor-integrated system, there’s a TAB Wrapper Tornado built to streamline your workflow and protect your products.

Reliable, manual start orbital stretch wrapper designed for your everyday wrapping needs. No banding, no strapping, no boxes, crates, or corrugated containers are needed anymore.

Semi-automated TAB Wrapper that works from the seat of your forklift featuring enhanced safety, efficiency, and programmable wrap settings. Essential for those who have high-volume needs.

The TAB Wrapper Lightning is the compact solution for operations that want the performance of a full-size TAB Wrapper Tornado in a smaller, more flexible package.

Equipped with dual stretch wrap film dispensers for faster wrapping and extra film coverage. Ideal for heavy or wide loads.

Engineered for maximum efficiency, the Perfect Storm features a built-in infeed and discharge conveyors that eliminate the need to drive your forklift through the wrapping ring. Simply set the pallet on the conveyor and press the “Start” button.

Compact orbital wrapper designed specifically for wrapping individual boxes or small packages. The perfect solution for your e-commerce or logistics operation.

Maximize The Potential of Your TAB Wrapper Tornado

with our specialized line of plastic stretch wraps designed specifically for our machines.

Enhance the Standard models with these optional upgrades:

PALLET WRAPPING ROI CALCULATOR:

“First seeing the TAB WRAPPER TORNADO in 2014 at FABTECH, I was a bit surprised a shipping product made my top 10 potential advancements list to review for my entire plant. After seeing further automated advancements on the TAB WRAPPER TORNADO in 2017, we made our purchase. The only regret was waiting 3 years to do so. Not all wrapping machines are created equal and the TAB WRAPPER TORNADO’S unique wrapping technology has proven to be super-fast and reliable. We now have extreme confidence when our packaging leaves our dock!”

Nick LaVigne

Plant Manager

Monti Incorporated

Greenwood, SC