Preventative Maintenance Kits

Now it’s even easier to do routine maintenance on the TAB Wrapper Tornado orbital wrapper and keep the stretch wrap machine running in peak condition. These new Preventative Maintenance Kits are pre-assembled with the exact OEM components and/or sub-assemblies required to replace key wear parts and systems fast, safely, and as easily as possible. We typically stock these in our Reading, Pa. facility and ship out within 24 hours – but why risk any downtime at all when you can keep these kits on hand in your facility?

Call to order (610)921-0012 or contact us here.

See the current lineup of kits below:

Blade/Seal Replacement Kits come with two cutter blades, cutter head strike pad, and companion seals based on the cylinder of the machine model. Call when ordering to verify which kit is required.

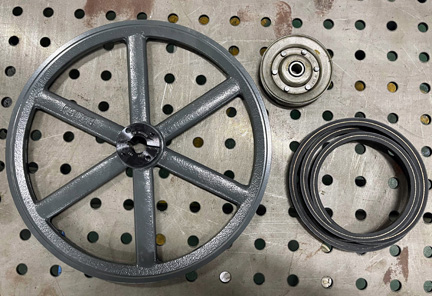

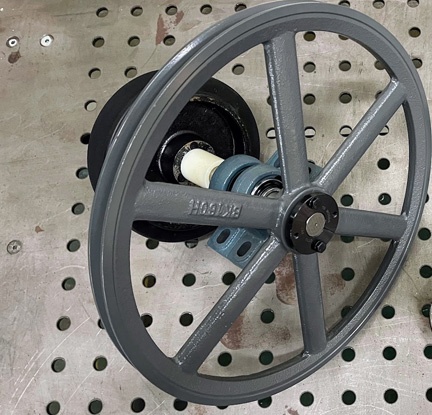

Complete Drive Wheel Assembly Kit provides the complete system with fly wheel, bearing belt and V idler preassembled with shaft, two pillow block bearings and key ways in one package.

Bottom Guide Wheel Kit features the guide wheel arm pre-assembled with the wheel, arm, 3/4” bearing, shaft, and 3/4” crown nut.

Top Guide Wheel Kit features the guide wheel with shaft and two pillow block bearings all preassembled. Look for rubber tread wear to assess need for replacement.

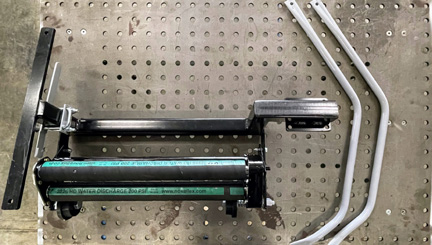

Auto-Cut Exhaust Blower Kit arrives pre-assembled. Check this system periodically for cracks in the plastic

as a sign that replacement may be needed.

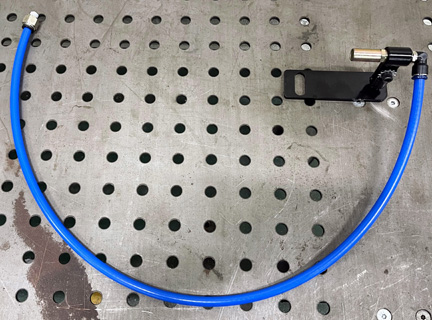

Auto-Cut Device Kit features a complete automated cut and wrap device that arrives pre-assembled for easy

replacement. Typical service life of 10 years depending on pallet wrapping volume and level of care.

“Steel King has had two TAB WRAPPER TORNADOS® in service for more than a year, running 120 plus hours per week. The team at TAB WRAPPER was extremely helpful from the start of our project as both were integrated into a semi-automated packaging process. The TAB WRAPPER TORNADOS® provided a cost effective solution for Steel King, resulting in significant cost savings in our packaging process by eliminating excess banding, labor, and shipping claims.”

MIKE MILHEISER

custom machine lead

steel king

stevens point, wi