TAB WRAPPER TORNADO - STANDARD

Streamlined Pallet Wrapping for Every Business

The Standard TAB Wrapper Tornado is a reliable solution for fast and secure pallet wrapping. Built for durability and versatility, it adapts to a wide range of pallet sizes and product types, helping businesses streamline operations, reduce costs, and protect product loads.

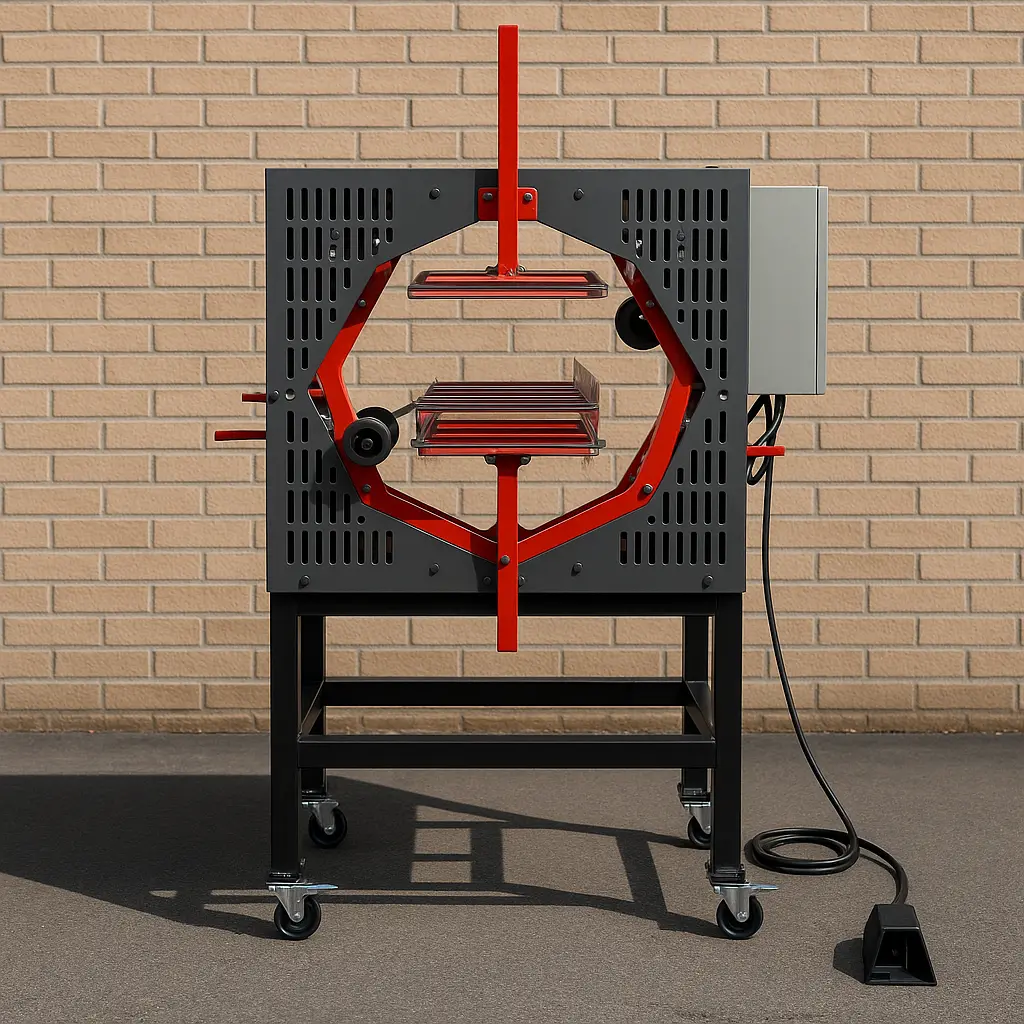

STANDARD MODEL IN ACTION

WHY CUSTOMERS CHOOSE THE STANDARD MODEL

For operations that regularly wrap pallets, small inefficiencies can add up to significant costs. The Standard model is designed to solve common problems in pallet wrapping operations through horizontal stretch wrapping technology.

- Automation: Semi-automatic operation with corded remote control enables smooth integration into existing workflows

- Cuts labor and material costs: Reduce stretch film waste and eliminate hand-wrapping

- Boosts efficiency: Wrap pallets in under 1 minute with a single operator

- Prevents freight damage: Secures loads to pallets for safe transport

- Improves employee safety: Reduces injuries, back strain, and workers’ comp claims

- Versatile Wrapping: Handles standard pallet loads as well as pallets with long, irregular, or oversized products

Curious how much you could save by automating your wrapping process? Try our ROI Calculator to see your potential savings.

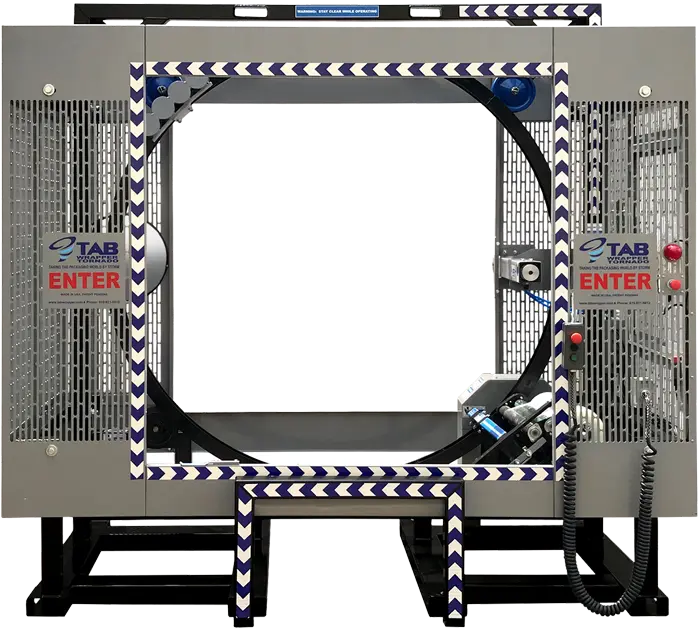

HOW THE STANDARD MODEL WORKS

With its intuitive process and automated wrapping technology, the Standard Model transforms pallet wrapping into a fast, user-friendly experience:

- The forklift operator positions the loaded pallet and securely attaches the stretch film to the pallet base to begin the wrapping process.

- Using a convenient corded remote control, the operator activates the system, allowing the operator to maintain a safe distance while controlling the wrapping operation.

- The Standard wrapper automatically encircles the entire pallet load with continuous 360° wrap coverage, bonding both the product and pallet together into one single, stable unit. This unique horizontal approach locks the film securely under the pallet, providing superior load stability compared to traditional vertical wrapping methods.

- Once the wrapping cycle is complete, the operator releases the remote button and cuts the film. The pallet is instantly ready for transport or storage with no additional banding, strapping, or securing materials needed.

Standard Model Sizes

- 80” Fits up to 48″ x 48″ skid

- 100” Fits up to 60″ x 60″ skid

- 115” Fits up to 50″ wide x 95″ tall

Have any other questions about the Standard Model or our other models? Find answers and more details on our FAQ page, or download our free stretch wrapper comparison guide to see how different wrapper types stack up.

Which Standard Tab Wrapper is Right for You?

| Model | Weight | Dimensions | Pallet Size | Electrical Requirements | Genius Control Compatible | Smart Control Compatible | Perfect Storm Compatible | Dual Dispensing Compatible |

|---|---|---|---|---|---|---|---|---|

| 80" Model | 2000 lbs | 9' x 4'2" x 8'6" | 48" x 48" | 110 volt |  |  |  |  |

| 100" Model | 2500 lbs | 10'6" x 4'2" x 10'2" | 60" x 60" | 220 volt |  |  |  |  |

| 115" Model | 3000 lbs | 11'6" x 4'2" x 11'10" | 50" wide x 95" tall | 240 volt, Single Phase |  |  |  |

Our Complete Tab Wrapper Tornado Lineup

The TAB Wrapper Tornado lineup includes a variety of models, from everyday pallet wrapping to high-volume, fully automated operations. Whether you need a reliable manual option, advanced programmable controls, or a conveyor-integrated system, there’s a TAB Wrapper Tornado built to streamline your workflow and protect your products. Download our free buyer’s guide to compare all seven models side-by-side.

The TAB Wrapper Lightning is the compact solution for operations that want the performance of a full-size TAB Wrapper Tornado in a smaller, more flexible package.

Semi-automated TAB Wrapper that works from the seat of your forklift featuring enhanced safety, efficiency, and programmable wrap settings. Essential for those who have high-volume needs.

Semi-automated model featuring smart programmable controls for streamlined operation and customizable wrap settings.

Equipped with dual stretch wrap film dispensers for faster wrapping and extra film coverage. Ideal for heavy or wide loads.

Engineered for maximum efficiency, the Perfect Storm features a built-in infeed and discharge conveyors that eliminate the need to drive your forklift through the wrapping ring. Simply set the pallet on the conveyor and press the “Start” button.

Compact orbital wrapper designed specifically for wrapping individual boxes or small packages. The perfect solution for your e-commerce or logistics operation.

Maximize The Potential of Your TAB Wrapper Tornado

with our specialized line of plastic stretch wraps designed specifically for our machines.

Enhance the Standard models with these optional upgrades:

PALLET WRAPPING ROI CALCULATOR:

Steve Lewis

Owner

Oregon Powder Coating

Tangent, OR