TAB WRAPPER TORNADO – GENIUS CONTROLS

Semi-Automatic Wrapping, the Genius Way

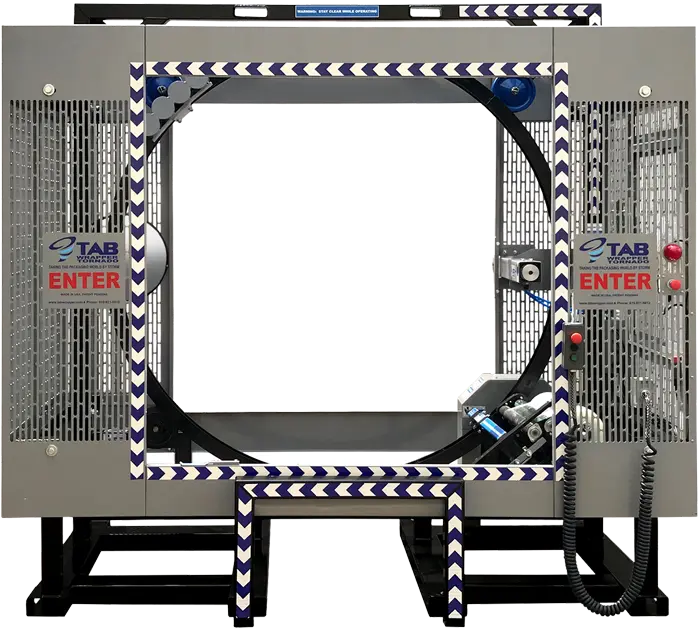

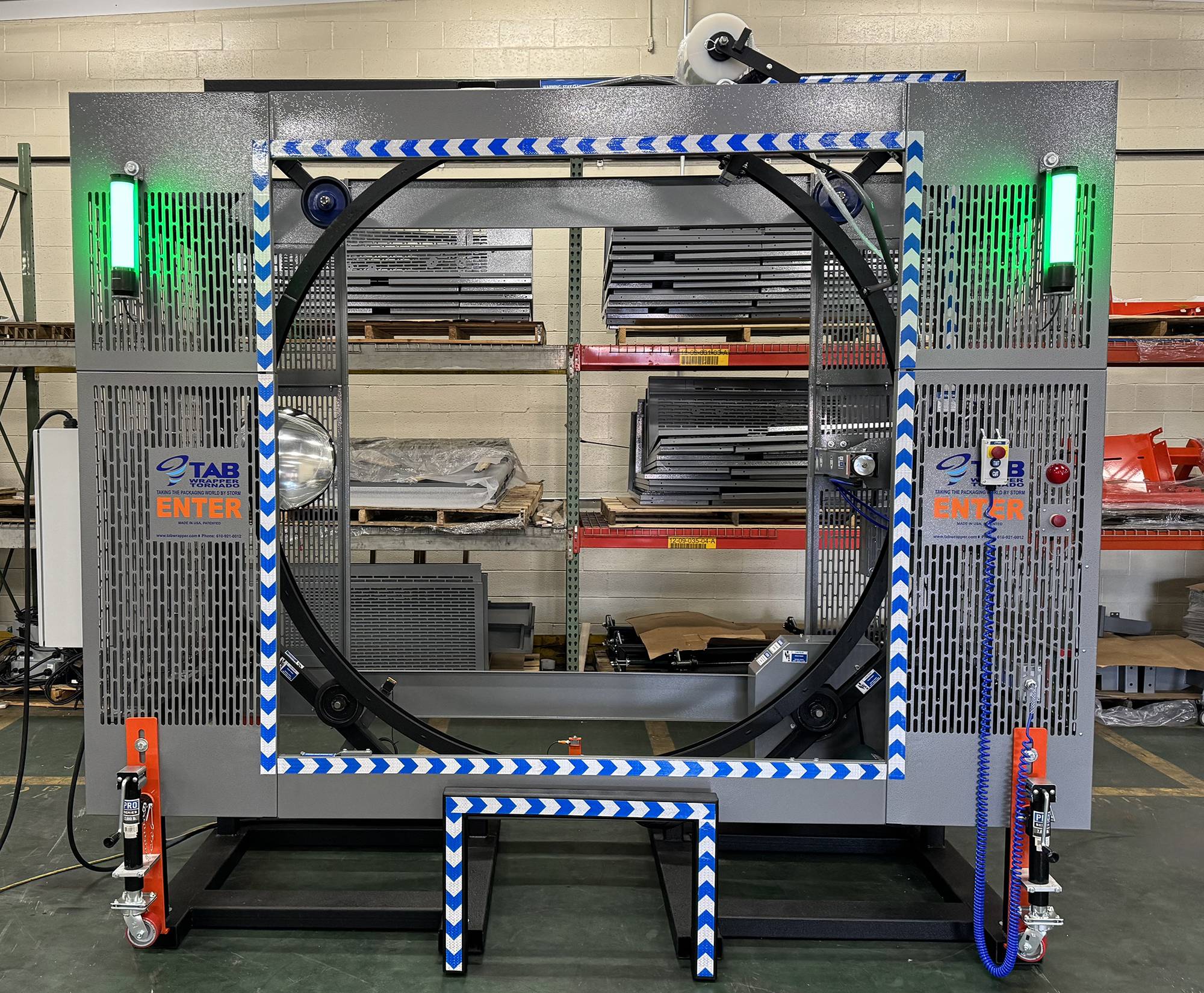

The TAB Wrapper Tornado with Genius Controls is a semi-automatic pallet wrapping machine that delivers a seamless, operator-friendly pallet wrapping process. With semi-automatic technology, a single forklift driver can wrap a pallet load in just minutes, eliminating the need for back-breaking manual stretch wrapping while ensuring consistent, reliable load protection.

GENIUS CONTROLS IN ACTION

WHY CUSTOMERS CHOOSE GENIUS CONTROLS

The TAB Wrapper Tornado with Genius Controls further the convenience of automation, combining advanced technology with ease of use to make your packaging operations faster, safer, and more reliable. Designed for mid to high-volume environments, this semi-automatic stretch wrap machine minimizes operator involvement while ensuring every pallet is securely wrapped and ready for transport.

- Efficient stretch wrapping: Reduce downtime and increase throughput with fast, reliable wrapping.

- Operated by one forklift driver: Streamlines operations while freeing staff for other tasks

- Eliminates manual strain: Protects workers from cuts, scrapes, and injuries associated with manual wrapping

- Consistent, secure loads: Pallets are unitized and stabilized, resisting shifting in transit without banding, strapping, crates, or boxes

- Intuitive, operator-friendly controls: Touch-screen HMI with integrated training videos makes it easy for any operator to learn and run the machine safely

- Smart diagnostics and alerts: Multi-color stack lights, audible alarms, and maintenance notifications provide instant feedback to keep operations smooth

Curious how much you could save by automating your wrapping process? Try our ROI Calculator to see your potential savings.

HOW GENIUS CONTROLS WORK

The TAB Wrapper Tornado with Genius Controls is a semi-automatic stretch wrap machine designed to efficiently secure pallet loads while reducing the risks that come with manual wrapping. By automating key steps, it protects products from damage in transit and safeguards workers from the cuts, scrapes, and strain of hand wrapping.

Here’s how the process works:

- The forklift operator raises a pallet load and drives toward the center of the wrapping ring.

- The orbital stretch wrapping machine automatically detects the forklift and scans the pallet dimensions.

- Stretch film is applied 360° around and under the pallet in overlapping layers for maximum stability.

- Once wrapping is complete, the system automatically cuts the film and holds it in place for the next load.

Genius Controls Model Sizes

- 80″ Fits up to 48″ x 48″ skid

- 100″ Fits up to 60″ x 60″ skid

- 115″ Fits up to 50″ wide x 95″ tall

Have any other questions about the Genius Controls Model or our other models? Find answers and more details on our FAQ page, or download our free stretch wrapper comparison guide to see how different wrapper types stack up.

Our Complete Tab Wrapper Tornado Lineup

The TAB Wrapper Tornado lineup includes a variety of models, from everyday pallet wrapping to high-volume, fully automated operations. Whether you need a reliable manual option, advanced programmable controls, or a conveyor-integrated system, there’s a TAB Wrapper Tornado built to streamline your workflow and protect your products. Download our free buyer’s guide to compare all seven models side-by-side.

Reliable, manual start orbital stretch wrapper designed for your everyday wrapping needs. No banding, no strapping, no boxes, crates, or corrugated containers are needed anymore.

The TAB Wrapper Lightning is the compact solution for operations that want the performance of a full-size TAB Wrapper Tornado in a smaller, more flexible package.

Semi-automated model featuring smart programmable controls for streamlined operation and customizable wrap settings.

Equipped with dual stretch wrap film dispensers for faster wrapping and extra film coverage. Ideal for heavy or wide loads.

Engineered for maximum efficiency, the Perfect Storm features a built-in infeed and discharge conveyors that eliminate the need to drive your forklift through the wrapping ring. Simply set the pallet on the conveyor and press the “Start” button.

Compact orbital wrapper designed specifically for wrapping individual boxes or small packages. The perfect solution for your e-commerce or logistics operation.

Maximize The Potential of Your TAB Wrapper Tornado

with our specialized line of plastic stretch wraps designed specifically for our machines.

Enhance the Standard models with these optional upgrades:

PALLET WRAPPING ROI CALCULATOR:

“We liked how the driver could operate the machine without getting on and off the forklift – this is a much faster, more efficient way to wrap our pallets. Now, we’re always on time and on schedule without scrambling to meet deadlines, and we have the capacity to handle our growth without needing to hire.”

Steve robinson

president

pitt meadows plumbing & mechanical Systems

maple ridge, bc canada