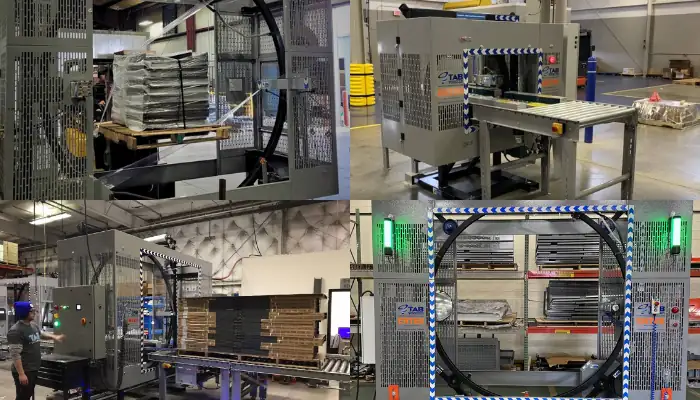

Selecting the right orbital stretch wrapper can transform how you protect your products during shipping and storage. TAB Wrapper offers seven distinct orbital stretch wrapping systems, each designed for specific applications and automation needs. Here’s a straightforward guide to help you choose the right model.

Why Orbital Stretch Wrapping?

Before diving into specific models, we need to understand what sets TAB Wrappers apart: orbital stretch wrapping technology. Unlike traditional turntable or rotary arm wrappers that only wrap vertically, orbital wrappers provide complete 360° horizontal coverage — wrapping over the top and underneath your product. This creates a fully unitized load secured directly to the pallet with complete weather protection and superior load security.

The TAB Wrapper Lineup

We offer multiple models that work around your needs.

Lightning Model

Best for: Smaller bundles and unpalletized items

Automation: Manual

Ring Sizes: 24″, 36″

The Lightning model simplifies bundle wrapping into a quick, repeatable process. Operators place the product, attach the film, and press the foot pedal to start the wrap. In seconds, the ring secures the item through a simple process.

Standard Model

Best for: Small to medium operations seeking basic automation

Automation: Semi-automatic

Ring Sizes: 80″, 100″, 115″

The Standard TAB Wrapper is an economical option, featuring a strong steel construction. This model features semi-automatic film handling with corded or wireless remote control options. Perfect for companies transitioning from hand wrapping to automated solutions.

Smart Controls

Best for: Medium-large operations

Automation: Semi-automatic

Ring Sizes: 80″, 100″, 115″

The Smart Controls model emphasizes automation and ease of use for medium to large operations. It features auto-cut and wrap capabilities for consistent, hands-free operation and VFD controls. Powered conveyors can also be integrated with this control package.

Genius Controls

Best for: High-volume operations focusing on efficiency

Automation: Semi-automatic

Ring Sizes: 80″, 100″, 115″

The Genius Controls offer advanced automation features designed to maximize productivity and consistency. These controls sense the pallet for contactless operation, automatically cut and hold the film to prepare for the next load, and provide email updates to keep operators and management informed. Integrated training videos streamline onboarding, while audible and visual alarms deliver real-time status updates. Additionally, safety relay diagnostics ensure reliable and continuous operation.

Dual Dispensing

Best for: High-throughput operations needing faster wrap cycles and added film coverage

Automation: Semi-automatic

Ring Sizes: 80″, 100″, 115″ (for pallet loads) The Dual Dispensing is designed with two film rolls for faster wrap cycles and heavier loads, making it ideal for wide or heavy pallets that require extra coverage and product protection. This model also requires the Smart Controls operating package and includes two auto-cut devices, in addition to two dispensing units

Perfect Storm

Best for: Operations that have heavy or wide loads requiring maximum security

Automation: Fully automated

Ring Sizes: 80″, 100″, 115″

The Perfect Storm operates with a proprietary sensor array for precise load detection and wrapping accuracy. It includes built-in infeed and discharge conveyors for a seamless, fully automated workflow. The system can integrate load cells and/or a dimensional system for weight verification and data collection. A touch-screen HMI with built-in video training makes operation and onboarding simple.

Box Wrapper

Best for: E-commerce and smaller item fulfillment

Automation: Fully automated

Ring Size: 40″

Specifically designed for a flow of smaller items. The Box Wrapper model features built-in infeed/discharge conveyors and powered slider belt guides with auto-feeding, eliminating manual load positioning. It’s ideal for operations shipping individual boxes or small bundles without palletizing.

Quick Selection Guide

Need twice the speed? Dual Dispensing.

Starting with automation and don’t have a big need yet? Standard Model.

Need to wrap small bundles? Lightning Model.

Running high volumes? Genius Controls.

Need maximum load security? Perfect Storm.

Want more automation at a lower price point? Smart Controls.

Shipping e-commerce orders? Box Wrapper.

Key Considerations

Load Type: Bundles, pallets, or small boxes? This determines which models will physically accommodate your product.

Volume: How many loads per day? Higher volumes justify increased automation that reduces operator involvement and ensures consistency.

Automation Level: Do you want semi-automatic operation with operator control, or fully automated contactless operation? This affects labor requirements and consistency.

Special Requirements: Need dual film for extra security? Quick training videos for your employees? Continuous flow for fulfillment? Match specialty features to your operational challenges.

We’re Here To Help

Choosing the right orbital stretch wrapper isn’t just about wrapping; it’s about improving efficiency, safety, and product protection across your operation. Every TAB Wrapper is built to deliver dependable performance, reduce labor costs, and create consistent, secure loads ready for transport or storage. Contact us today to learn more about the full range of capabilities offered by the TAB Wrapper line.