City Pipe

Orbital wrapper eliminates injuries, speeds packaging

Pipe, valve, fitting distributor improves packing of bulky, awkward loads

At City Pipe & Supply’s Odessa, Texas facility, Vice President Charlie Justice was watching his packaging team race to meet deadlines. With 100 pallet loads of heavy pipe, valves, and fittings to wrap before the day ends, some employees were getting hurt in the process.

City Pipe & Supply couldn’t afford packaging failures. Yet their manual wrapping process was creating serious problems:

- Recurring worker injuries: Hand lacerations, cuts, and back injuries occurred every 3-4 months during the wrapping process

- Dangerous two-person operation: Workers had to pass heavy film rolls back and forth while working under raised pallets, risking head injuries

- Inconsistent quality: Manual wrapping led to load failures 1-2 times per year during transit, with products falling off trucks — creating $10,000+ losses and highway safety hazards

- Overtime: Two workers could only wrap 80 pallet loads per day, requiring constant overtime to meet deadlines

The final straw came when another worker lacerated his hand while cutting film. Justice knew he had to find a safer solution.

“We’d been in a fast-paced growth mode for so long that scrambling to meet every deadline became the norm,” says Justice. “We were always on time, but at a cost.”

The TAB Wrapper Tornado Solution

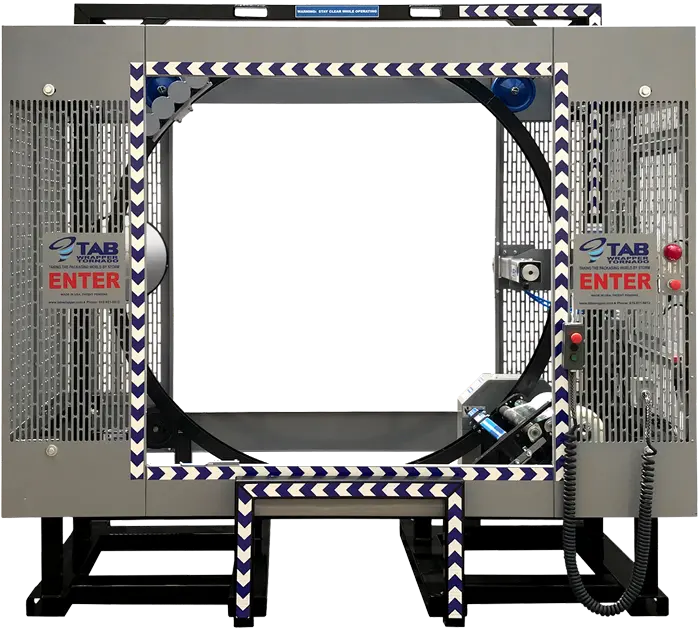

After researching alternatives, Justice invested in the 80-inch TAB Wrapper Tornado orbital stretch wrapper. Unlike traditional manual wrapping methods, this patented technology wraps plastic film 360 degrees around and under the pallet, creating a completely secure load.

Key Benefits Include:

- Automation: Forklift operators simply drive into the wrapping ring and press start

- Superior load security: Film wraps underneath the pallet, eliminating load shifting during transit

- One-person operation: A single operator can manage the entire process from the forklift seat

- Handles challenging products: Ideal for City Pipe’s heavy, oddly-shaped valves, fittings, and pipe loads

- Weather-resistant packaging: Creates durable, professional loads ready for outdoor storage or transport

Implementation and Results

The successful results at City Pipe & Supply were evident.

Key Results Included:

- Zero injuries: Eliminated all cuts, scrapes, and workers’ compensation claims from wrapping operations

- Productivity increase: One operator now wraps 150 pallet loads per day versus two workers wrapping 80 loads manually

- Improved shipping record: Eliminated load shifting in transit and rejects caused by damage

- Eliminated overtime costs: Faster wrapping eliminated the daily scramble to meet deadlines

- Improved brand identity: Blue stretch film matching company colors creates instant job site recognition

After just 30 minutes of training, forklift drivers were comfortable operating the machine. “It worked great!” says Justice. “Everybody loves it, and nobody wants to go back to wrapping by hand.”

Read the full featured article here from The Tube and Pipe Journal.

Ready to Eliminate Wrapping Injuries and Double Your Packaging Speed?

TAB Wrapper offers proven orbital stretch wrapper technology for operations handling heavy, challenging loads — all available in multiple configurations to fit your specific requirements.