H&H Metals

A Metal Fabrication Company Achieves Great Efficiency By Embracing A New Orbital Wrapping Technology

The Challenge

When H&H Metals Vice President Jim Huff decided to mass-produce J-J Hooks, the metal connectors for concrete highway barriers, he knew efficiency would make or break this new idea. As a high-volume, low-margin product, every minute mattered.

The Colorado fabricator had grown from a basement startup with $6.39 to a $5 million operation in a 64,000-square-foot facility. But their packaging process was holding them back from the next level of growth.

Their manual wrapping operation was causing some major problems:

- 3-person process: Required pulling two skilled sheet metal technicians off production to help wrap

- 20 minutes per pallet: Manual wrapping a pallet took 15-20 minutes.

- Inconsistent wrap quality: Never achieved tight wraps despite using excess film, leading to products shifting in transit

- Production interference: At 20 pallet loads per day, packaging was stealing valuable production time

The oddly-shaped J-J Hooks made matters worse; they refused to stack neatly and constantly threatened to slide off pallets during the manual wrapping process.

“The manual way we were wrapping pallet loads for pickup and delivery wasn’t going to work for us anymore,” said Huff.

The TAB Wrapper Tornado Solution

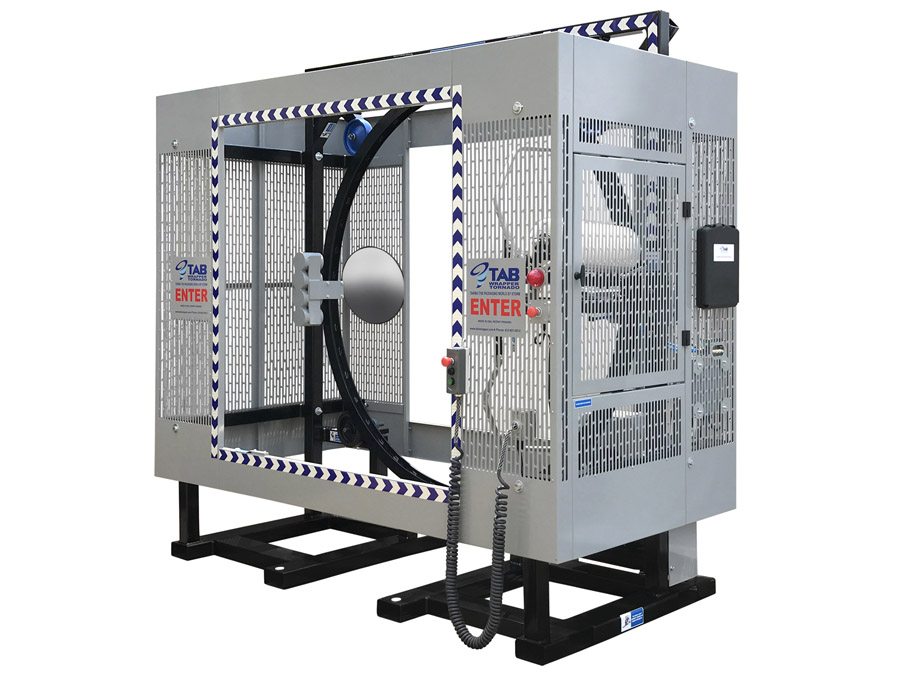

Remembering a machine he’d seen at Fabtech in 2012, Huff invested in the 80-inch TAB Wrapper Tornado, featuring a wireless remote and automated cut system, as part of a $250,000 automation upgrade to their facility.

The orbital wrapper’s patented technology wraps plastic film 360 degrees around and under entire pallet loads, creating completely unitized loads ready for transport or storage.

Key Benefits Include:

- Forklift integration: Operators control everything via wireless remote without leaving their forklift seat

- Handles odd product shapes: Wraps challenging items like J-J Hooks that refuse to stack uniformly

- Infinite length capability: Stationary ring design accommodates products up to 12 feet long

- Automatic labeling: The machine enables users to automatically include a label within the plastic wrapping, preventing mislabeling and errors in processing

The system is simple to operate: forklift drivers raise the load, center it in the wrapping ring, and then press the start button. The machine automatically wraps multiple layers and stops when complete.

Implementation and Results

The transformation of H&H Metals’ wrapping process was immediate.

Key Results Included:

- Productivity increase: Cut wrapping time from 20 minutes to less than 1 minute per pallet

- Labor reduction: Reduced from a 3-person to a 1-person wrapping operation

- Load stability: 4,000-pound J-J Hook pallets now stack securely on top of each other

- Zero freight damage: Eliminated product shifting and transit damage

- Customer satisfaction: Multiple customers commented on the professional wrapping quality

“The drivers just love it,” says Huff. “They don’t have to get in and out of the cab, and it’s better for them ergonomically.”

The machine proved to be so effective that H&H Metals now wraps “just about everything that goes out the door,” including light-gauge aluminum and stainless steel flashing for windows, in lengths up to 12 ft., on a 12-ft. pallet, as well as an array of other products on standard 40-in. and 48-in. pallets.

Read the full case study on FAB Shop Magazine Direct.

Learn More About TAB Wrapper Solutions

TAB Wrapper offers proven orbital stretch wrapper technology, available in multiple configurations with wireless remote and automation options, for metal fabrication operations handling challenging products.