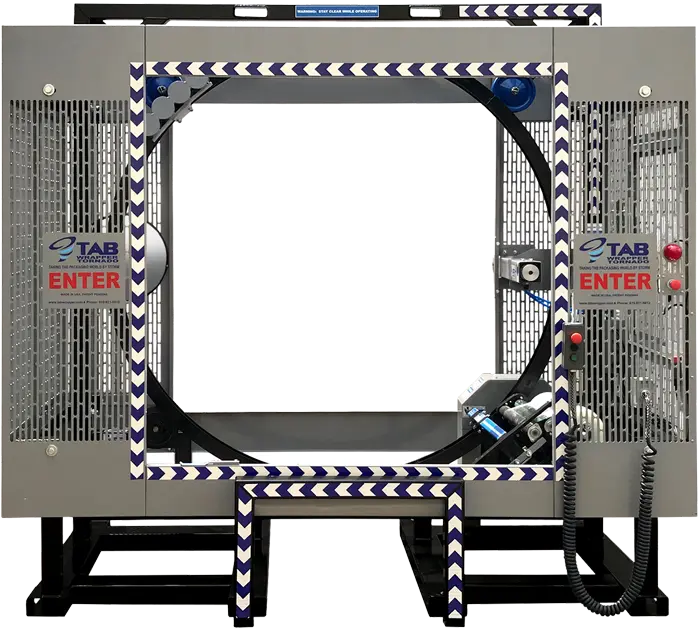

TAB WRAPPER TORNADO - BOX WRAPPER

Compact Orbital Wrapping for Small Parts & Products

The TAB Wrapper Tornado Box Wrapper model brings automated orbital wrapping technology to small parts packaging. Designed for items that traditional manual wrapping methods struggle with, it secures loose components to backing materials and bundles long products into tight units, creating packages that ship safely with less dunnage and often without boxes entirely.

BOX WRAPPER MODEL IN ACTION

WHY CUSTOMERS CHOOSE THE BOX WRAPPER MODEL

For businesses shipping small parts and products, loose items, or products with awkward shapes, manual wrapping and packaging methods generate waste, require more materials, and slow down employees. The Box Wrapper model automates your packaging process through orbital stretch wrapping technology. Here’s what our customers love about the Box Wrapper:

- Reduces packaging costs: Eliminate boxes, dunnage, and excess packing materials

- Perfect for e-commerce: Creates shipping-ready packages ideal for carriers like UPS, FedEx, and USPS

- Secures loose items: Bonds small pieces to cardboard backing for safe transport

- Bundles long items: Combines multiple rods, sticks, or tubes into single units for easy transport

- Complete automation: Powered guides and gravity rollers handle the entire product wrapping process automatically

- Touch screen controls: Built-in training videos and a simple interface ensure consistent, error-free operation

- 360° protection: Orbital wrapping goes around and under products for complete product security

Curious how much you could save by automating your wrapping process? Try our ROI Calculator to see your potential savings.

HOW THE BOX WRAPPER MODEL WORKS

The TAB Wrapper Tornado Box Wrapper combines orbital wrapping technology with user-friendly automation in a compact design that handles everything after you press start:

- Place items on the infeed conveyor and press start on the touch-screen control.

- The conveyor belt then guides products on gravity rollers, automatically feeding your products into the 40″ wrapping ring.

- Smart positioning sensors detect the product width and automatically position items for optimal wrapping.

- The Box Wrapper encircles the entire load with full coverage, wrapping around and under both the cardboard backing and product to create a secure, unitized package.

- Products then discharge automatically after the wrapping process, fully protected and ready for storage or delivery.

Box Wrapper Model Size

- 40” wrapping ring

Have any other questions about the Box Wrapper Model or our other models? Find answers and more details on our FAQ page, or download our free stretch wrapper comparison guide to see how different wrapper types stack up.

Our Complete Tab Wrapper Tornado Lineup

The TAB Wrapper Tornado lineup includes a variety of models, from everyday pallet wrapping to high-volume, fully automated operations. Whether you need a reliable manual option, advanced programmable controls, or a conveyor-integrated system, there’s a TAB Wrapper Tornado built to streamline your workflow and protect your products.

Reliable, manual start orbital stretch wrapper designed for your everyday wrapping needs. No banding, no strapping, no boxes, crates, or corrugated containers are needed anymore.

Semi-automated TAB Wrapper that works from the seat of your forklift featuring enhanced safety, efficiency, and programmable wrap settings. Essential for those who have high-volume needs.

Semi-automated model featuring smart programmable controls for streamlined operation and customizable wrap settings.

Equipped with dual stretch wrap film dispensers for faster wrapping and extra film coverage. Ideal for heavy or wide loads.

Engineered for maximum efficiency, the Perfect Storm features a built-in infeed and discharge conveyors that eliminate the need to drive your forklift through the wrapping ring. Simply set the pallet on the conveyor and press the “Start” button.

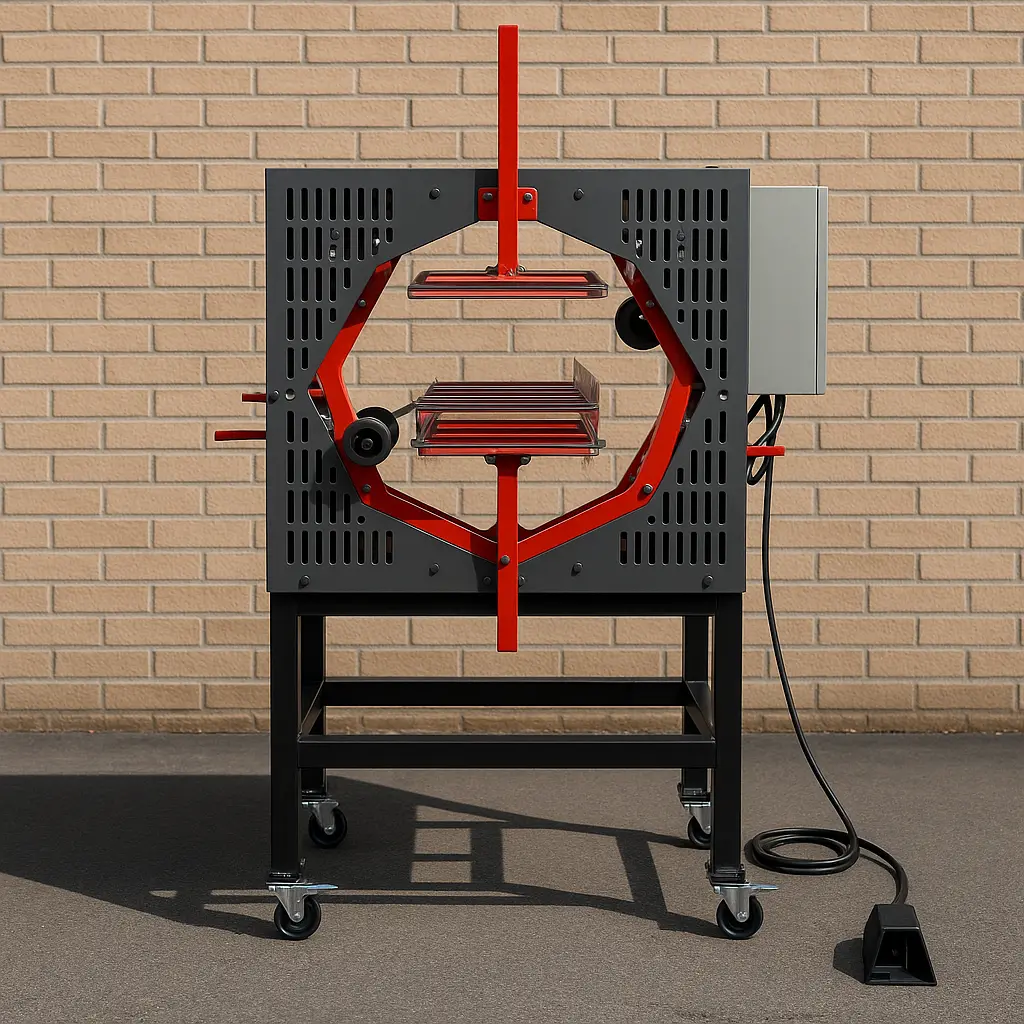

The TAB Wrapper Lightning is the compact solution for operations that want the performance of a full-size TAB Wrapper Tornado in a smaller, more flexible package.

Maximize The Potential of Your TAB Wrapper Tornado

with our specialized line of plastic stretch wraps designed specifically for our machines.

Enhance your TAB Wrapper models with these optional upgrades:

PALLET WRAPPING ROI CALCULATOR:

James Morgan

Director of Corporate Operations

Siskin Steel and Supply

Chattanooga, TN