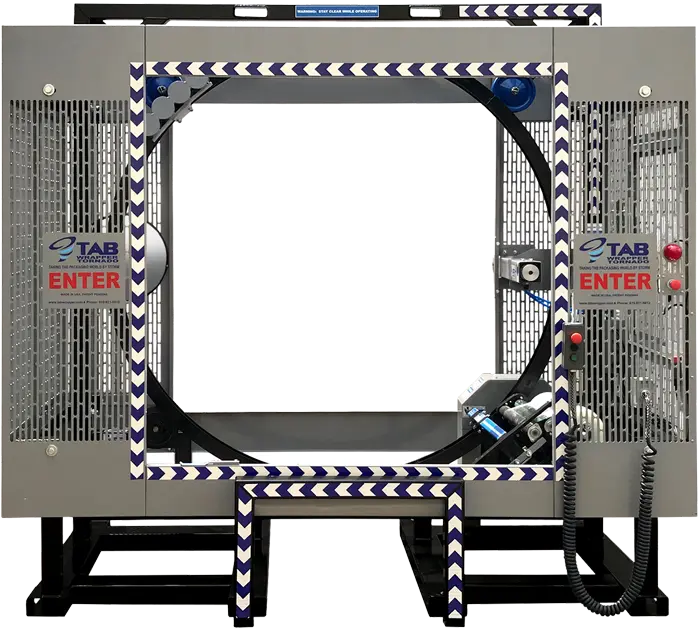

TAB WRAPPER TORNADO - DUAL DISPENSING

Double the Protection for Heavy Loads

The Dual Dispensing TAB Wrapper delivers an enhanced wrapping experience with two independent stretch film dispensers to wrap pallet loads. Built for heavy-duty applications and challenging product loads, it provides superior film coverage and faster wrapping speeds, helping businesses protect high-value products.

DUAL DISPENSING MODEL IN ACTION

WHY CUSTOMERS CHOOSE THE STANDARD MODEL

When one roll of stretch wrap isn’t strong enough, the Dual Dispensing model steps up to the challenge. With two independent film dispensers working simultaneously, this horizontal stretch wrapping system tackles the toughest packaging requirements.

- Load security: Two stretch film layers provide more security for heavy, wide, or unstable loads

- Increased wrapping speed: Dual dispensers reduce time spent on wrapping pallet loads while increasing film coverage

- Versatile film options: Use different stretch wrap grades or types simultaneously for customized product protection

- Prevents freight damage: Loads stay secure during transport and handling

- Ideal for challenging products: Perfect for oversized, irregular, or high-value items requiring extra protection

- Auto-Cut: Features dual automated cut-and-wrap devices that automatically cut both film rolls at once, doubling the speed and efficiency

Curious how much you could save by automating your wrapping process? Try our ROI Calculator to see your potential savings.

HOW THE DUAL DISPENSING MODEL WORK

The process maintains the same simple operation as other models while providing enhanced protection through the dual film system.

- The forklift driver approaches with a loaded pallet and uses the remote to activate the system

- Horizontal stretch wrapper technology deploys two film dispensers simultaneously.

- Both dispensers work together to apply continuous 360° wraps around the entire load.

- Each dispenser operates independently, allowing the use of two different stretch wrap grades with varying properties (stretch, puncture resistance, opacity, clarity, color).

- Products are fully secured with no need for additional strapping, banding, or secondary securing.

Dual Dispensing Model Sizes

- 80” Fits up to 48″ x 48″ skid

- 100” Fits up to 60″ x 60″ skid

- 115” Fits up to 50″ wide x 95″ tall

Have any other questions about the Dual Dispensing Model or our other models? Find answers and more details on our FAQ page, or download our free stretch wrapper comparison guide to see how different wrapper types stack up.

Our Complete Tab Wrapper Tornado Lineup

The TAB Wrapper Tornado lineup includes a variety of models, from everyday pallet wrapping to high-volume, fully automated operations. Whether you need a reliable manual option, advanced programmable controls, or a conveyor-integrated system, there’s a TAB Wrapper Tornado built to streamline your workflow and protect your products. Download our free buyer’s guide to compare all seven models side-by-side.

Reliable, manual start orbital stretch wrapper designed for your everyday wrapping needs. No banding, no strapping, no boxes, crates, or corrugated containers are needed anymore.

Semi-automated TAB Wrapper that works from the seat of your forklift featuring enhanced safety, efficiency, and programmable wrap settings. Essential for those who have high-volume needs.

Semi-automated model featuring smart programmable controls for streamlined operation and customizable wrap settings.

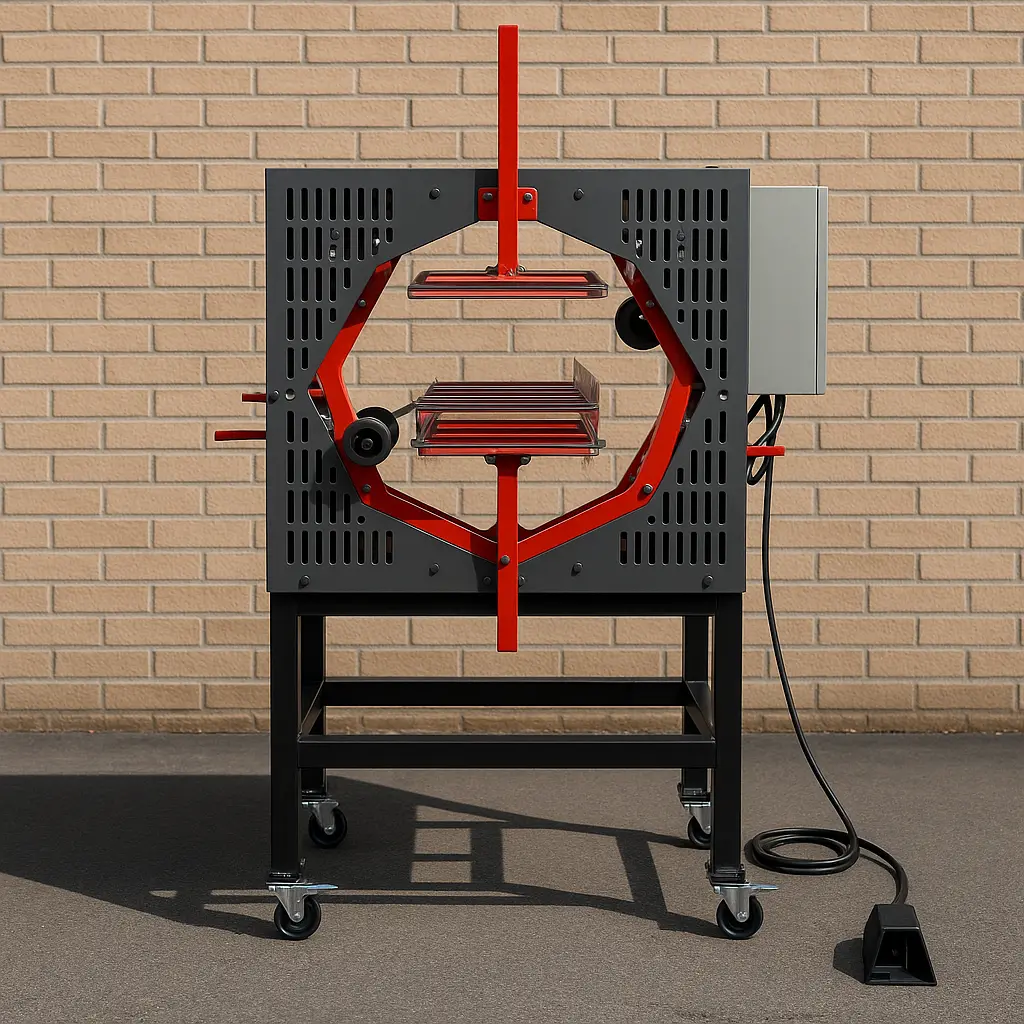

The TAB Wrapper Lightning is the compact solution for operations that want the performance of a full-size TAB Wrapper Tornado in a smaller, more flexible package.

Engineered for maximum efficiency, the Perfect Storm features a built-in infeed and discharge conveyors that eliminate the need to drive your forklift through the wrapping ring. Simply set the pallet on the conveyor and press the “Start” button.

Compact orbital wrapper designed specifically for wrapping individual boxes or small packages. The perfect solution for your e-commerce or logistics operation.

Maximize The Potential of Your TAB Wrapper Tornado

with our specialized line of plastic stretch wraps designed specifically for our machines.

Enhance the Dual Dispensing Models with these optional upgrades:

PALLET WRAPPING ROI CALCULATOR:

“We’re getting a much better, more secure wrap every time, even on our longest skids and it wouldn’t even be possible to wrap them by hand – I just love this machine!”

mike roeder

president

penn sheet metal

allentown, pa