TAB WRAPPER TORNADO – PERFECT STORM

Fully Automated Wrapping, Perfected

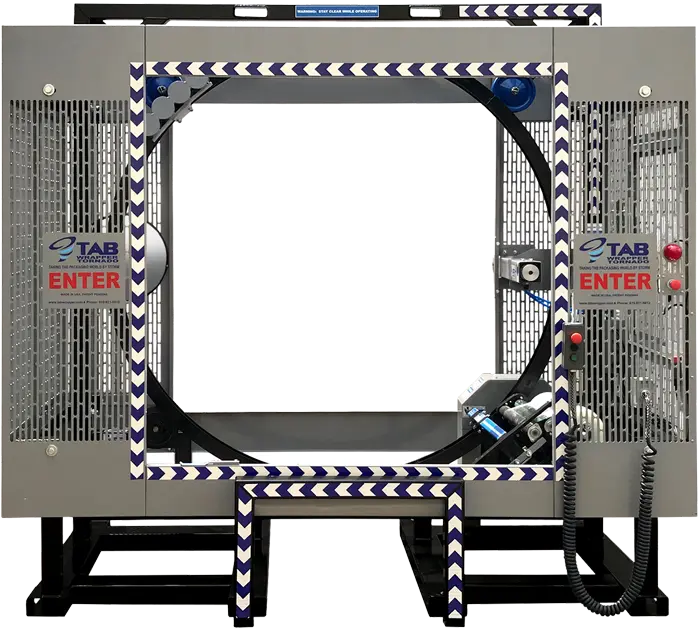

The Perfect Storm TAB Wrapper Tornado takes pallet wrapping to the next level with its fully automated stretch wrapping capabilities. Featuring a proprietary sensor array, this orbital stretch wrapping system automatically detects pallet loads, scans product dimensions, calculates the ideal wrap pattern, and completes the wrap without operator contact. It’s the safest, fastest, and most efficient way to protect high-volume palletized products.

THE PERFECT STORM IN ACTION

WHY CUSTOMERS CHOOSE THE PERFECT STORM MODEL

With unmatched automation and precision, the Perfect Storm eliminates manual steps and ensures every load is securely unitized.

- Hands-free operation: Sensors detect, scan, and calculate wrap requirements automatically

- Fast throughput: Wraps and discharges pallet loads in as little as 15 seconds.

Labor savings: A single operator can manage the process safely in under one minute - Complete pallet load protection: Provides continuous 360° wrap coverage, eliminating the need for banding, strapping, or bulky packaging

- User-friendly controls: Touch-screen HMI with intuitive menus and built-in video training

- Scalable automation: Customizable with optional accessories for conveyors, load cells, and accumulation zones

Curious how much you could save by automating your wrapping process? Try our ROI Calculator to see your potential savings.

HOW THE PERFECT STORM MODEL WORKS

The Perfect Storm streamlines pallet wrapping like never before, minimizing operator involvement while maximizing efficiency and load protection. Getting started is simple:

- The forklift operator places the pallet load on the infeed conveyor.

- The operator steps back and starts the system using the touch-screen HMI.

- The Perfect Storm automatically scans the load dimensions and determines wrap requirements.

- The system feeds, wraps, and secures the pallet load in protective stretch film.

- The pallet discharges fully wrapped and ready for transport or storage — all in less than one minute.

Perfect Storm Model Sizes

- 80” Fits up to 48″ x 48″ skid

- 100” Fits up to 60″ x 60″ skid

- 115” Fits up to 50″ wide x 95″ tall

Have any other questions about the Perfect Storm Model or our other models? Find answers and more details on our FAQ page, or download our free stretch wrapper comparison guide to see how different wrapper types stack up.

Our Complete Tab Wrapper Tornado Lineup

The TAB Wrapper Tornado lineup includes a variety of models, from everyday pallet wrapping to high-volume, fully automated operations. Whether you need a reliable manual option, advanced programmable controls, or a conveyor-integrated system, there’s a TAB Wrapper Tornado built to streamline your workflow and protect your products. Download our free buyer’s guide to compare all seven models side-by-side.

Reliable, manual start orbital stretch wrapper designed for your everyday wrapping needs. No banding, no strapping, no boxes, crates, or corrugated containers are needed anymore.

Semi-automated TAB Wrapper that works from the seat of your forklift featuring enhanced safety, efficiency, and programmable wrap settings. Essential for those who have high-volume needs.

Semi-automated model featuring smart programmable controls for streamlined operation and customizable wrap settings.

Equipped with dual stretch wrap film dispensers for faster wrapping and extra film coverage. Ideal for heavy or wide loads.

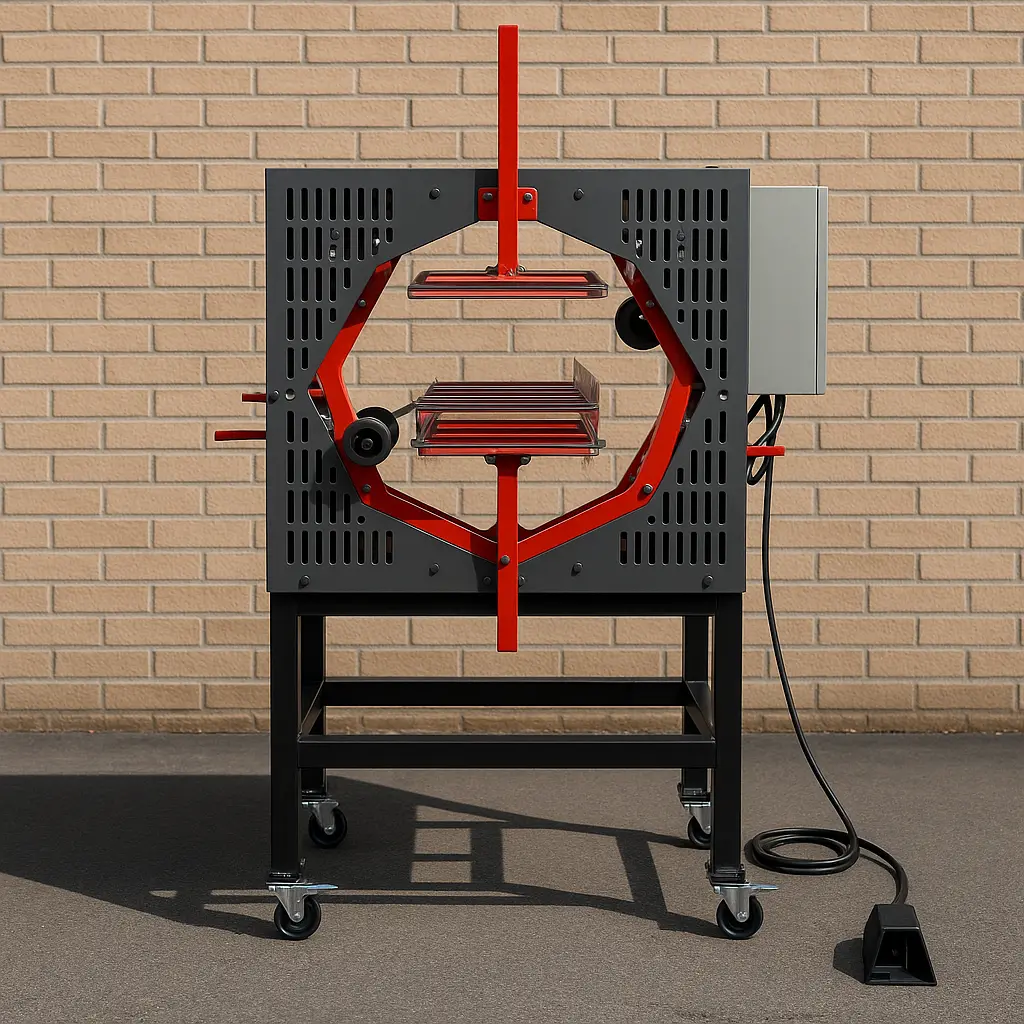

The TAB Wrapper Lightning is the compact solution for operations that want the performance of a full-size TAB Wrapper Tornado in a smaller, more flexible package.

Compact orbital wrapper designed specifically for wrapping individual boxes or small packages. The perfect solution for your e-commerce or logistics operation.

Maximize The Potential of Your TAB Wrapper Tornado

with our specialized line of plastic stretch wraps designed specifically for our machines.

Enhance the Standard models with these optional upgrades:

PALLET WRAPPING ROI CALCULATOR:

Mike Huskey

Vice President of Operations & Supply Chain

Fiberon

New London, NC