Stretch Wrap

To take full advantage of the TAB Wrapper Tornado and promote maximum uptime, try the line of plastic stretch wrap selected specifically for these orbital wrapping machines. The TAB stretch wrap line was specified after many years of testing different types and grades of plastic stretch film on the TAB Wrapper Tornado by wrapping a huge variety of challenging pallet loads.

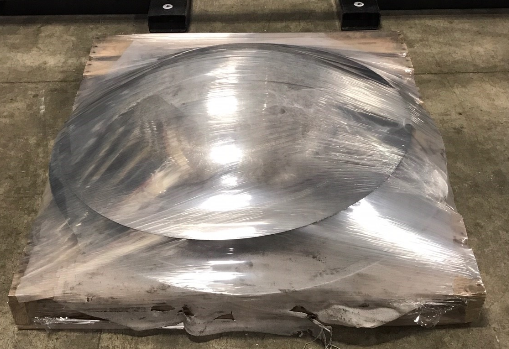

Extra heavy, hollow and round, oddly shaped, too sharp to handle, long and flimsy, loose groupings, awkward center of gravity – if it can be wrapped and delivered, we’ve probably tested it already. That’s how we learned to match different types of stretch wrap with different types of pallet loads to get superior performance from the plastic wrap and use less film per pallet load.

Types of Stretch Wrap Film For Sale

The TAB stretch wrap films for orbital wrappers are cast plastic instead of blowmolded plastic so the film has only one-sided cling and unwinds very quietly. The type of pallet load determines the recommended stretch wrap based on the level of puncture and tear resistance, force to load ratio, temperature sensitivity, and other film properties needed.

The TAB wraps come in 90-, 80-, and 65-gauges that deliver the load containment strength of heavier duty 120-gauge and 80-gauge films – this means less film is needed per pallet load. The strech film is stocked in our Reading, PA facility in clear, blue, and black. But we’ll also match custom corporate colors and add logos and branded graphics for an extra level of marketing value.

For packaging pros who haven’t yet automated the wrapping process, try TAB hand stretch wrap. This is a clear, cast plastic film for manual pallet wrapping. It provides high strength and unwinds quietly just like stretch wraps for automated orbital wrappers but is easy to apply by hand.

Try TAB as a reliable stretch wrap film supplier. Call Joel Brizek at (610)921-0012 or jbrizek@tabindustries.com for a free quote.

Timothy P. Ippolito

Director of Operations

Fidelity Technologies Corporation

Reading, PA