Understanding the difference between horizontal and vertical axis wrapping is critical to making the correct decision on what is best for wrapping your product on a pallet. We understand that the differences between these two can be difficult, and we want to make sure that you make the right decision.

Let’s break it down together.

Horizontal vs. Vertical Axis Wrapping: Clearing Up the Confusion

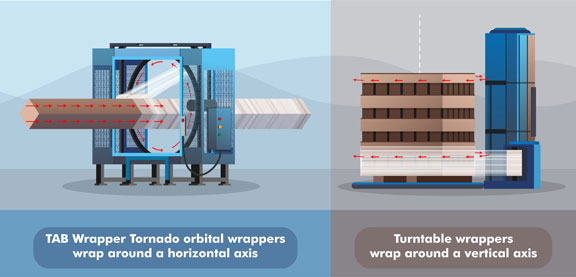

For pallet wrapping, the terms horizontal and vertical axis wrapping refer to the orientation in which the stretch wrap is applied.

- Horizontal axis wrapping is when the stretch wrap is applied around the pallet of products horizontally. This is where an orbital wrapper shines.

- Vertical axis wrapping is when stretch wrap is applied to the pallet of products vertically, like a flagpole standing up. Vertical wrappers, such as a rotary arm stretch wrapper or horizontal turnable wrapper, can be used for this.

Here’s where it can get confusing: despite its name, the horizontal turntable wrapper actually wraps on a vertical axis. (We’ll explain more on that shortly.)

What Axis Does an Orbital Wrapper Use?

An orbital wrapper is a true horizontal-axis stretch wrapper. The pallet load remains stationary while the machine spins stretch wrap around it on a horizontal axis. This allows 360-degree wrapping to secure both the pallet and the product tightly, helping prevent shifting during transit or sliding in storage.

Our TAB Wrapper Tornado orbital wrapper is operated by a single person, making the process not only effective but also easier and more efficient than others. A single operator can fully wrap a pallet quickly, all without removing it from the lift truck. The lift truck operator raises a pallet load and drives toward the center of the wrapping ring, and the TAB Wrapper Tornado automatically wraps the pallet load.

Whether you’re wrapping beams, pipes, or irregular loads, our orbital wrapper does what turntable wrappers simply can’t — wraps 360 degrees around a product’s horizontal axis for total load stability.

Understanding the Horizontal Turntable Wrapper (That Wraps Vertically)

Horizontal turntable wrappers, as noted above, actually wrap on a vertical axis. In this method, the pallet load is placed on a rotating turntable, and as the platform spins, stretch wrap is applied around the sides of the load, or in this case, around its vertical axis. The stretch wrap roll usually moves vertically up and down to cover the height of the product, while the load rotates in place.

This type of wrapping has limitations: since only the sides are wrapped, not the top or bottom, loads can shift or become unstable during transit. A horizontal turntable wrapper would be more ideal only for uniform, stable loads like stacked boxes.

Choosing the Right Pallet Wrapper For Your Products

The choice between an orbital wrapper and a horizontal turntable wrapper is critical, as it affects the efficiency, safety, and product quality.

If you’re planning to wrap a number of different boxes or products of different sizes, shapes, and weights on the same pallet at the same time, or if you’re planning to wrap long products on rectangular pallets, or very lightweight or oddly shaped products, then wrapping with a turntable wrapping machine is not an ideal solution. Orbital wrappers can wrap anything that can fit in the machine’s wrapping ring.

Orbital Wrapping Machine:

- Best for mixed loads of different shapes, sizes, or weights

- Long products like rods, pipes, or extrusions

- Lightweight or top-heavy products

- Horizontal axis wrapping

Horizontal Turntable Wrapper:

- Best for consistent product sizes

- Uniform in both weight and shape

- Low in the product’s center of gravity

- Vertical axis wrapping

For some companies, it may make sense to automate the packaging process with both an orbital wrapper and a horizontal turntable wrapper. The buying decision depends primarily on the type of pallet loads, then on the volume, floor space, staffing levels, budget, and other factors.

If you’re unsure what’s best for your needs, reach out to us today.